Adhesives/Sealants

Aerospace room temperature adhesive

Two-component adhesive for aircraft. It is used to bond the main wing of an aircraft, etc.

| Material | Two-component and room-temperature curing adhesive.(Epoxy resin) |

|---|---|

| Capacity | 122g |

| Unit | THINKY MIXER ARE-310 / ARE-250CE |

| Operation time setting | Mixing Mode 2000rpm 45sec Defoaming Mode 2200rpm 2min |

| Compounding ratio | Main agent/Hardener 100:22(w/w) |

| Material Viscosity | Main agent :13000-6000 mPa・s Hardener :0.3-0.7 mPa・s |

| Specific gravity | Main agent:1.15 Hardener:1 |

Related data

-

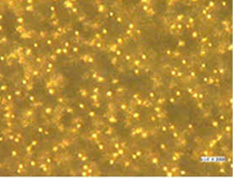

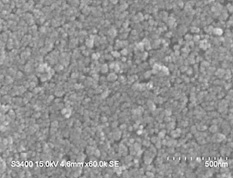

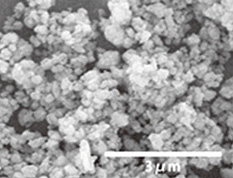

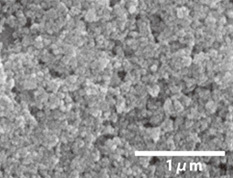

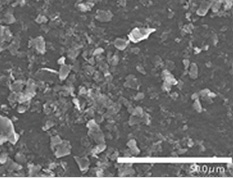

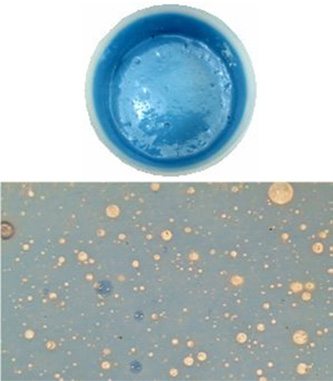

Before

-

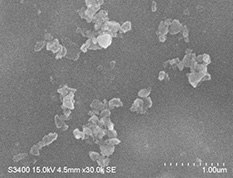

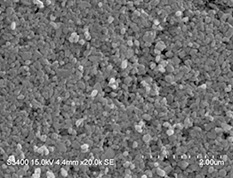

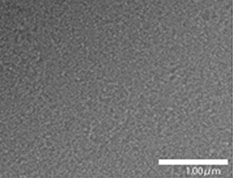

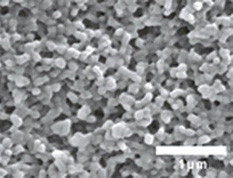

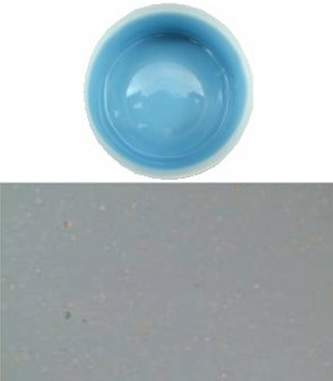

After

Supported products

THINKYMIXER (Non Vacuum) ARE-312

・Improved mixing power and defoaming power

・Suppresses the temperature rise of the main unit and allows temperature measurement inside the device

・Communication function supports traceability and control from external devices

・CE certified model (EN61010-1; 2010+A1:2019)

・Long-term operation is possible even with highly loaded materials (maximum operation time 30 minutes)

・Improved safety with the addition of an impact sensor

THINKYMIXER (Non Vacuum) ARE-310

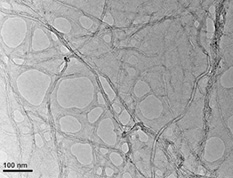

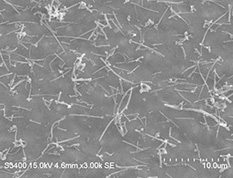

・Supports a wide range of materials, including high-viscosity materials and nano fillers

・The 2 modes of mixing and deaeration achieve dispersion and deaeration of high-viscosity materials in a small amount of time

・Cold-insulated, heat-resistant adapter enables support of various material characteristics

・Wide variety of adapters for using various containers

・Memory and step-operation functions for controlling and executing operating conditions

・Unique air-cooling system

THINKYMIXER (Non Vacuum) ARE-250 CE

・230V ready

・The 2 modes of mixing and deaeration achieve dispersion and deaeration of high-viscosity materials in a small amount of time

・Cold-insulated, heat-resistant adapter enables support of various material characteristics

・Wide variety of adapters for using various containers

・Memory and step-operation functions for controlling and executing operating conditions

・CE certified model is available