User Interview ーAiwa Gishi Seisakusho (A manufacturer of prosthetic limbs)

January 07, 2020|Interview

We would like to share with our readers our interview with Mr. Shintaro Hayashi, representative of Aiwa Gishi Seisakusho, a manufacturer of prosthetic limbs that are designed to enhance decorative or aesthetic appeal in particular.

It may be known to some of our readers that Mr. Hayashi is a prosthetist who was featured in the TV program “Professional – Shigoto no Ryugi (My Style of Work)” broadcast by NHK (Japan Broadcasting Corporation) in 2014. He was the creator of a pair of “barefoot” shoes for the leading man who ran barefoot through the fields in a Taiga drama (a long-running historical drama series) produced by NHK.

We asked him about his commitment to prosthetic limb making and the use of our Thinky Mixer.

Tell us about Aiwa Gishi Seisakusho.

Aiwa Gishi Seisakusho deals with custom-made silicone prosthetic fingers and limbs (prosthetic hands and legs). It specializes in realistic prosthetic hands.

The company pays attention not only to appearance, such as nails, wrinkles, blood vessels or spots, but also to the functional aspect in an effort to meet our customer’s requirements. In the case of a prosthetic hand, for example, when using a knife or fork, it is a matter of course that the hand has to take a form that looks natural with the utensil. However, we pay meticulous attention by applying hard silicone to the dented part of the palm to make it easy to hold the fork. By mixing a wide variety of additives, we adjust the degree of strength or hardness and sometimes use 10 or more types of silicone creatively in making a single prosthetic hand.

A prosthetic hand specifically for holding a fork. The dented part at the center of the palm certainly felt harder.

His ruling passion for making prosthetic limbs

When it comes to reality, I think it means not only physical appearance but making something that “looks like that particular person” as well. What we make is a body part that was lost, such as a hand, but reproducing that part alone is far from sufficient. Even if it is a single finger lost, that person’s life is in it so it is important to ask him/her to reveal to us his/her life as a whole, i.e., how he/she leads his/her life. A hand shows an expression that is nearly the same as a face, so we ask that person to let us touch his/her hand and during a meeting, we observe his/her body language or face closely in order to get a feel of who he/she really is. We take a photograph of his/her face as well. We value our conversations with our clients and try to come up with something that exceeds their expectations. That is what our professional skills are all about. A prosthetic maker who lacks passion will not be able to tug at his/her clients’ heartstrings. If a prosthetic hand does not feel right not only for the one who puts it on but also for his/her family members who touch it, we will start all over again. We play for keeps.

Unless we create something that makes a member of his/her family say, “This is Dad’s hand!” it would not be acknowledged as part of the body by the client.

We have met around 2,000 people face-to-face and made prosthetic limbs for them thus far. There were quite a few who shed tears of joy when their prosthetic limbs were ready; we have been consciously trying to give them a breathtaking moment that makes them feel the “tangible difference.”

Moreover, because it is a realistic prosthetic limb, that specific part of the person alone should not remain young and should age with the user. The company was founded in 2004 and I have clients with whom I have enjoyed a professional relationship for more than 20 years since I started making prosthetic limbs as a freelancer. The percentage of repeat clients is high.

A variety of prosthetic hands that the company has its ruling passion for. Diverse attributes, including gender and age, can be surmised.

Movable prosthetic limbs

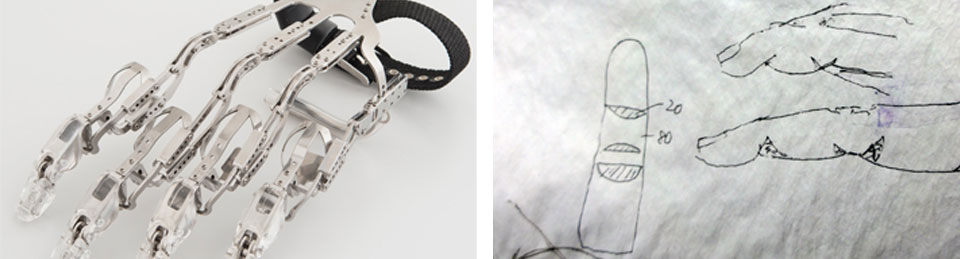

In recent years, we have been working on making movable prosthetic limbs called the X-Finger®. This technology originated in the U.S., but we had conducted research and development for about five years so that it could be made available to the public, introduced, and maintained promptly in Japan, and have become its authorized manufacturer in Japan.

As our company is not large enough to hire a researcher, we seek cooperation from a university professor through an industry-academia partnership and work on improvements, including ways to increase grip force. When we consult with the professor on something of which we are sentient as a manufacturer, he/she responds to it with specific numbers or formulas; we and the professor have much in common as devoted professionals, so we have been able to enjoy a good relationship.

X-Finger® is entirely made of metal, but in the future, we are contemplating adding a realistic silicone appearance to develop it further so that it may be accepted by as many people as possible.

Left: X-Finger

Right: Mr. Hayashi takes notes as soon as he comes up with an idea.

Do you receive orders not only from Japan but the rest of the world as well?

Orders mostly come from within Japan. Those who watched the TV program “Professional – Shigoto no Ryugi (My Style of Work)” broadcast by NHK in 2014 still come and visit us. We have also received inquiries from Asia and Russia. Japanese people who live overseas visit us to have their prosthetic limbs made when they return home temporarily as well.

In Northern Europe, for example, those who have no hands or legs appear to fit in everyday scenes naturally, so not many people call on prosthetic limbs to be realistic and on the contrary, some quite often say that it is gross because it is too realistic. If you bring a prosthetic limb with you into a country with deteriorated peace and order, you may be accused of something you haven’t done….

In the first place, only basic learning is required to become a qualified prosthetist and studies of realistic prosthetics are not mandatory; that seems to be the case in a large number of countries. I received a student from Togo, Africa as a trainee and gave him technical guidance a little while ago. In Africa, there are still quite a few people who lose their limbs to infection, so they seem to need quantity. I feel that requirements for prosthetic limbs vary from country to country depending on environmental or cultural circumstances. Including accepting students, we are actively disclosing our techniques so that prosthetic limbs can reach as many people as possible.

The phase in which people are surprised to see our realistic prosthetics at a trade show has passed and due in part to the fact that we shared our skills with South Korea, I feel that realistic prosthetics have increasingly spread in Asia in particular.

Data of an actual hand and inverted data are printed out on a 3D printer and fine-tuned further.

What is the role of the Thinky Mixer in prosthetic limb making?

We mainly use the Thinky Mixer in making colors for silicone. To produce realistic prosthetic limbs, we layer various colors of silicone, so color reproducibility holds the key. Foam diffuses light, making it difficult to identify the real color. With the Thinky Mixer, foam is not generated so it is easy to see the real color, and this is the reason why we decided to deploy it.

We found that subtle differences in skin color were delicately reproduced.

Moreover, it took us a whole week to get rid of foam manually but after introducing the Thinky Mixer, the time was dramatically shortened.

The Thinky Mixer also helps us improve the strength of silicone as well. It takes time for even a craftsperson to get rid of unevenness when powder is mixed with silicone, and the Thinky Mixer is quieter than a washing machine in the morning, which is truly helpful.

To tell you the truth, we borrowed a demo machine and returned it several years before we actually purchased one. We thought that “we don’t need it because we can mix by hand,” but manual mixing inevitably resulted in unevenness, which was our concern. On second thought, given that “the Thinky Mixer is affordable and a tool that we can’t do without,” we introduced it five years ago.

I recommend the Thinky Mixer for small or medium-sized businesses that have to perform a wide variety of jobs with a small number of workers like us. By leaving the job of mixing to the Thinky Mixer, you would have spare time to do something else, which would make a big difference, I believe.

Making a prosthetic limb requires concentration. I believe that if you focus on your work, you will be able to make a good prosthetic quickly. As a company, we have tried to create an environment that allows the staff to focus on their work and come up with good prosthetics more quickly. It is unreasonable to try to resolve an issue by spending more time. If you work ceaselessly all through the night, you won’t be able to make a good product; nothing beats the power of concentration.

Besides time, when it comes to the simple job of mixing, the use of a dedicated machine definitely makes a difference in quality. Before using the Thinky Mixer, I thought manual mixing was good enough, but realized that previous manual mixing had been insufficient. Once you know what “real mixing” is using the Thinky Mixer, which features high-level reproducibility, I feel that the quality of mixing translates into great results.

Moreover, in the case of small or medium-sized businesses, the amount mixed is small and the mixer has rather limited use. Despite that, we have a lot of things that we need to try. We wonder whether mixing this or that using the Thinky Mixer would yield different results. Such attempts would help us broaden our manufacturing ideas.

By the way, isn’t the Japanese name Awatori Rentaro (meaning “mixer man who removes foam”) of the Thinky Mixer interesting? A machine that has a name comes across as more familiar, doesn’t it? I want our Awatori Rentaro to continue to work as hard as our staff.

Prosthetic limbs are being made. Silicone materials of slightly different colors are layered to make them.

After the interview

I was overcome with emotion when I held a prosthetic limb in which the client’s background has been incorporated and to which careful attention has been paid, in my hands. A professional craftsperson who comes up with a prosthetic limb, which is referred to as a work of art, described the convenience of the Thinky Mixer in words, which made us proud of the fact that our machine was used by such a person.

Aiwa began working on “work-style reform” as many as ten years ago and has established a unique work rhythm, he explained. We were immensely impressed by Mr. Hayashi’s efforts and initiatives, which were not confined to making prosthetic limbs, and the fact that he has tried various things in many other fields through trial and error.

We hope that the company will continue to make use of the Thinky Mixer so that its prosthetic limbs may reach as many people who need them as possible.

At the new company building that exudes a feeling of openness thanks to the vaulted ceiling are Mr. Hayashi and the staff together with the Benjamin tree, which is growing at an astonishing pace.

Aiwa Gishi Seisakusho (https://aiwa-gishi.jp/)

Address: 19-1 Sakae-cho, Nerima-ku, Tokyo

Foundation: January 2004