Let’s describe the attractive features of SR-500 for SMT (surface mounting technology).

August 19, 2019|Topic

Thinky Solder Paste Mixer SR-500, announced in 2005, is a specialized mixer for solder paste. Remove the solder paste container from the refrigerator, set it in Thinky Solder Paste Mixer SR-500 and push the start button. Then, the machine will optimize the condition of the solder paste in only a few minutes.

The Start of the Story: Solder paste used in our products

Around 1990, Thinky manufactured and sold measuring instruments as well as mixers for alginic acid. Solder paste (cream solder) is a material familiar to Thinky, because it has been used for SMT (surface mounting technology) boards, which constitute a part of measuring instruments. Solder paste is a very delicate material. Because it is sensitive to temperature changes and oxidizes quickly at high temperatures, it is sold frozen and must be stored in a refrigerator until it is ready for use. Since solder paste just removed from the refrigerator is cold and hard, it must be brought to room temperature when it is actually used. Because this process takes about two hours, in the past, a designated person had to come to work two hours early to take the solder paste out of the refrigerator. You might say that this was a process bottleneck.

One day, an employee put solder paste into the company’s mixer for alginic acid and tried to mix it. Then, the process that had taken more than two hours turned out to be finished in only a few minutes. It was recognized that this might be of practical use, and the development of mixers for solder paste began. At that time, Thinky was in transition from lead solder to the more expensive lead-free solder as environmental issues had to be considered. It was then found that similar results could be obtained in a short time for the lead-free solder as well. This was very well received at exhibitions and changed the conventional knowledge of the industry that two hours are required before kneading. In our company, this eliminated the necessity for a designated worker to come to work early to bring the solder paste to room temperature.

Relationship between SMT and solder paste

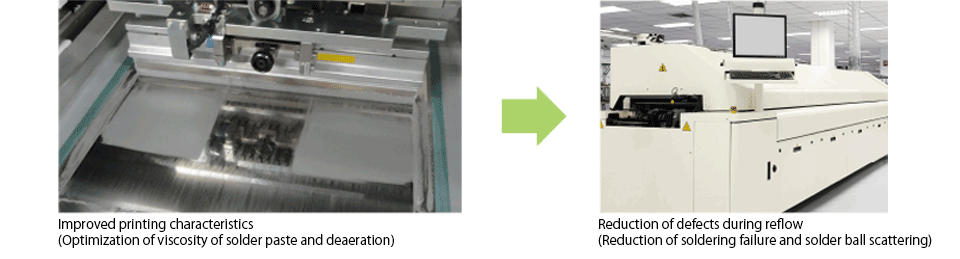

The most important and difficult part of the SMT process is the printing process. Poor quality of printing solder paste directly leads to failure of the board. The control of temperature, viscosity, and stirring and deaeration of solder paste constitute important and decisive factors in reducing defects in the SMT process.

Temperature control and condensation

Solder paste is made from solder and flux. Solder paste is usually stored in a refrigerator for the purpose of suppressing chemical reaction (mainly oxidation) of the solder and the flux. Oxidation of the solder paste reduces the activity of the flux, causing deterioration of the solderability (solder wettability). Furthermore, the process of bringing it to normal temperature (room temperature) before use is also very important. If the process of restoring to room temperature is insufficient and the lid is opened while the solder paste is colder than room temperature, condensation may form on the solder paste. The inclusion of moisture into the paste may cause scattering of solder balls in the later reflow process.

With SR-500, solder paste in a commercial container can be processed as is immediately after being taken out of the refrigerator. Therefore, the work that previously took about two hours, including the process of restoring to normal temperature, can be completed in only about ten minutes, including dispersion of the paste. The process can be carried out without opening the lid of the container and therefore is free of condensation.

Viscosity

Solder paste is a hard and heavy material. Therefore, its hand kneading is strenuous and time-consuming work, and differences among individuals directly affect the finish. A skilled spatula blender is required to control the quality of the solder paste by hand mixing. With its powerful stirring, SR-500 makes it easy for anyone to reproduce the proper conditions for solder paste. Stabilizing the condition of the solder paste leads to standardization of the printing of circuit boards.

The solder paste inside a container may become nonuniform in viscosity when refrigerated for several weeks. This is because solder particles with high specific gravity sink to the bottom of the container with time. It is desirable, therefore, that the solder paste be well stirred from the top to the bottom of the container so that the paste viscosity is uniform when being used. Thinky Mixer’s ability to uniformly mix high-viscosity material is most suitable for this process.

The viscosity of the solder paste plays an important role in problems such as missing solder, solder wetting, and solder sagging. Defects such as missing solder and solder wetting cause chipping (Manhattan phenomenon) and contact failure. If the viscosity of the solder paste is too high during screen printing, part of the paste may remain on the metal mask (printing plate) or “horns” may appear on the solder printed on the board. On the other hand, if the viscosity is too low, shape distortion (sagging) is likely to occur after printing.

When the solder paste is uniformly stirred to the appropriate viscosity in SR-500, squeegee movement becomes smooth and clogging of the metal mask is also reduced.

Stirring and deaeration

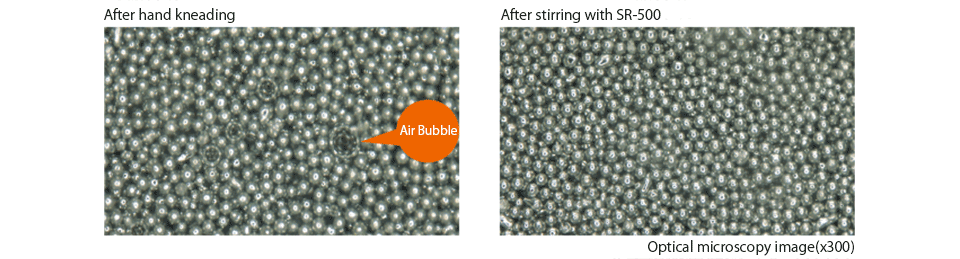

Excess moisture and air bubbles in the solder paste can cause the formation of solder balls and bridge failure. Stirring the solder paste in SR-500 eliminates bubbles and voids that cause solder balls. Combined with the absence of excess moisture because of the prevention of condensation, the deaeration of the solder paste while stirring results in reduced bridge failure.

In addition, light air bubbles move to the top and deaeration occurs because of the effect of centrifugal force due to the revolution by Thinky Mixer SR-500. At the same time, heavy material is pulled to the bottom of the container, preventing the adhesion of solder paste onto the inside surface of the lid. Therefore, loss of paste is also suppressed.

Evolution of SR-500 as a machine dedicated to solder paste

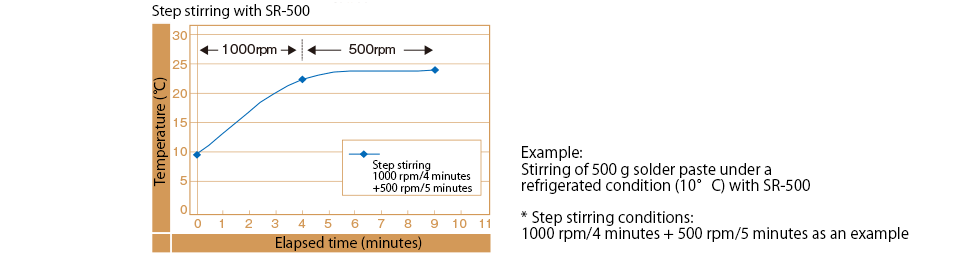

The predecessor of SR-500 had the problem that the temperature of the paste increased with continuous stirring at high speed. In the present SR-500, stirring is performed in two steps to prevent the solder paste from exceeding normal temperature. That is, first, the temperature is increased by high-speed rotation and then dispersion is continued by low-speed rotation while keeping the paste at room temperature. In addition, the user can change the rotation speed as well as set the operation time on a second-by-second basis, depending on the type and conditions of solder paste. SR-500 also has a convenient memory function that allows the user to register frequently used recipes.

For higher work efficiency, higher reproducibility and standardization

Thinky Solder Paste Mixer SR-500 came about by chance from a trial for fun, but it has become a product that helps solve various problems of solder paste.

There is a trend toward the miniaturization of chips and other products in the surface mounting industry, and the importance of management of solder paste quality is expected to increase in the future. In the hand kneading of solder paste, the adjustment of viscosity and dispersion is very time-consuming and requires a high level of technical skill. Also, differences among individuals may greatly affect the product quality. Using SR-500 specialized for solder paste, anyone can easily prepare solder paste in only ten minutes simply by taking a container of solder paste out from the refrigerator, setting it in SR-500, and then pressing a button. SR-500 can respond to the sudden increased need for extra solder and has excellent reproducibility of the quality.

SR-500 has the reputation of having few failures. Many customers have been using it for more than ten years. We hope SR-500 will be used by many people facing problems concerning solder paste and involved in the development of mounting technology.

Experience the lessening of the work burden of hand kneading as well as the elimination of the necessity for a worker to come in early. Feel free to request a trial use of SR-500 if you are interested.

–View product information

-Watch video

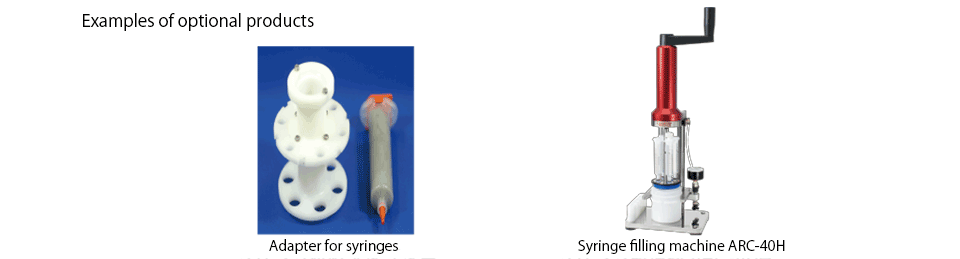

Optional items

● Adapters for containers of various solder manufacturers

The adapter 250AD-201 is supplied for a standard container of 500 g solder paste made in Japan. Adapters compatible with containers of other manufacturers are also available. (Contact us for special orders.)

● Adapter for syringes

Commercially available syringes can be attached directly to the optional syringe adapter, and re-dispersion and deaeration can be performed rapidly with SR-500. Using a syringe after deaeration will prevent air leakage (blank firing). In addition to solder paste, the adapter can also be used for deaeration chip bond.

● ARC-40H (manual syringe filling machine)

Up to four syringes can be loaded simultaneously. Materials such as solder paste and chip bond, mixed using SR-500 or other Thinky mixers, can be loaded into syringes by the customer.

● Multiple sensor (SR-500 will be supported in the future)

More precise temperature control becomes possible because the temperature of the material in the mixer can be checked in real time during stirring.