Production of high-energy cathodes for lithium-ion batteries with novel electrode structure

June 02, 2023|Topic

M.Sc. Jonas Oehm,

Prof. Dr.-Ing. V. Knoblauch

M.Sc. Jonas Oehm is shown in the photo above.

Aalen University of Applied Sciences, Institute for Materials Research, Germany

Product in use: ARM-310CE

Research Outline

Due to the increased demand for mobile, rechargeable batteries with ever higher energy and power densities, intensive research is being conducted into modifying the electrode structure in order to increase the active mass loading.

One possible approach is a three-dimensional structuring of the electrodes by using a cellular structure (e.g., a metal foam), which acts as a current collector. Due to the cellular structure, an electrically conductive structure is present within the active mass. This can increase the electrical conductivity of the electrode while increasing the integrity of the active mass layer. This should make it possible to increase the electrode thickness while reducing the amount of inactive components.

Importance of THINKY MIXER for Preparing Electrode Slurry

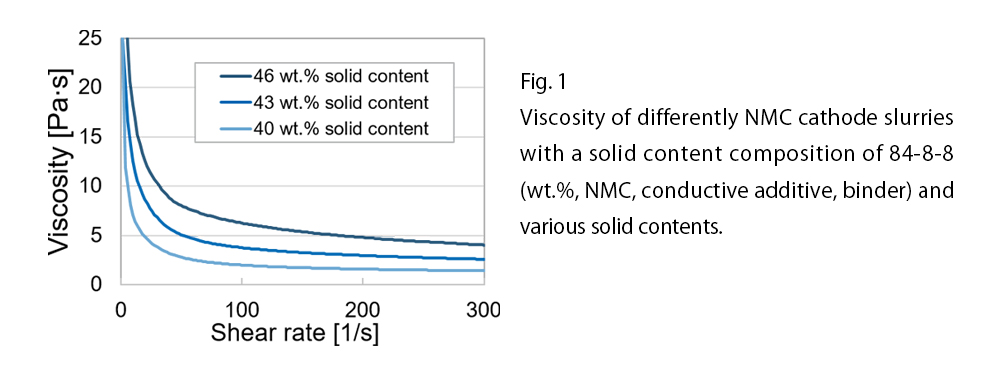

In the production of these foam electrodes with the highest possible active mass loading, the infiltration of the cellular structure with an electrode slurry is a decisive process step. The degree of infiltration depends to a large extent on the viscosity of the electrode slurry. In order to determine the optimum slurry composition for a given solids composition (e.g. 84 wt.% NMC, 8 wt.% conductive carbon black + graphite, 8 wt.% binder), three different cathode slurries with different solids contents were prepared using the Thinky ARM-310 planetary centrifugal mixer via a multi-stage process.

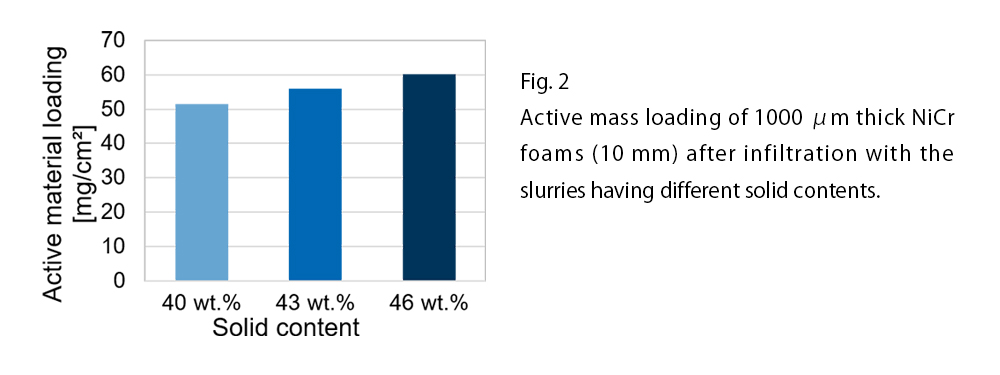

The viscosity curve of the three slurries in Fig. 1 shows that the viscosity increases with increasing solids content. Fig. 2 shows the active mass loading of 1000 µm thick NiCr foam rounds (Ø 10 mm, 450 µm cell size) after infiltration and drying with the different slurries. With increasing solids content, the active mass loading increases. With further increase of the solid content in the slurry, an inhomogeneous infiltration of the slurry is to be expected due to the increasing viscosity. With the Thinky ARM-310 planetary centrifugal mixer, various slurries with different compositions could thus be produced in a very short time and a suitable composition was identified.

About ARM-310CE

Highly competitive mixer for price wise. high durability, High reproducibility, for simultaneous processing of mixing, dispersing and deaeration of low-mid viscosity materials.

・Highly competitive price.

・Supports a wide range of materials, especially low-mid viscosity materials.

・Cold-insulated, heat-resistant adapter enables support of various material characteristics.

・Wide variety of adapters for using various containers.

・Memory and step-operation functions for controlling operating conditions.

・CE certified model is available.

Related products ARE-310, ARE-250CE