自転・公転ミキサーのパイオニア

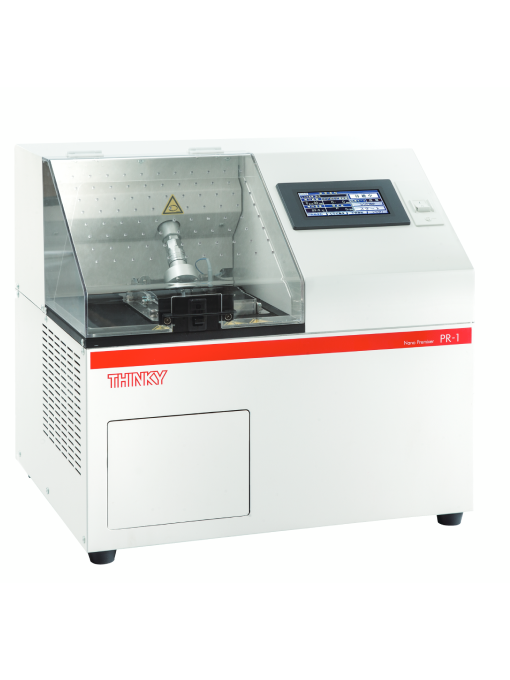

製品情報

PRODUCT

感動・感激を創造する

モノづくりを

どのような情報をお探しですか?

WHAT ARE THE

REQUIREMENTS?

情報ライブラリ

library

撹拌、脱泡に関する用語解説や技術資料、

ユーザーインタビューなどのお役立ち情報を掲載しています。

会社案内

ABOUT

「独創性」

「モノづくり」

「感動・感激」

株式会社シンキーは1970年の創業以来、「感動・感激を創造するモノづくり」をテーマに、それまで世になかったテクノロジーを独自開発してきました。現在、世界67カ国、累計47,000台以上の販売実績が有ります。

お問い合わせ・

資料お取り寄せ

サービスや製品に関するお問い合わせは、

下のボタンのリンク先よりご連絡ください。

各製品モデルの詳細がわかる

カタログをご用意しております。