Combination with peripheral equipment solves machine problems

High-accuracy defoaming of liquid agent in barrel containers

Nanoparticle production with reduced cost and time

Uniform mixing of high-viscosity binder and powder

Evenly dispersed materials fed without bubbles

Measurement accuracy improved by removing bubbles

Five-hour material processing shortened to only three to four minutes

Mixing and defoaming uniformity on which high-definition transfer depends

Simultaneous dispersion and defoaming! Reduced sedimentation and separation of particles

Highly uniform mixing and defoaming improve bonding strength

Defoaming time reduced to 1/10!

Mixing 30 colors a day achieved with inks having different densities, viscosities, and material properties

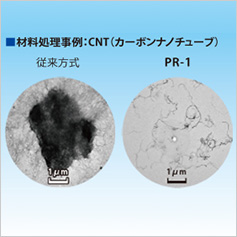

Functionality improved without cutting fibers

Changes in material properties during mixing are eliminated, resulting in work being completed in minutes.

Realization of time savings, quality improvement, blank beating resolution, and yield increase