Glossary: Agitation

December 19, 2018|Glossary

What is agitation?

Difference between agitation and mixing

Agitation may remind us of “mixing” at first, but, in a broad sense, it means the operation of “stirring and agitating“, and not necessarily mixing things together.

Think of a concrete mixing vehicle (agitator truck). The drum of the truck does not have the purpose of “mixing“, but rotates to “prevent separation and solidification” while transporting raw concrete produced at a concrete factory to a construction site.

In addition to “mixing”, agitation is often used for the purpose of “homogenization” (making an emulsion, a suspension, or a dispersion) and “mass transfer” (promotion of reaction and dissolution).

In everyday life, either whippers or electric mixers are used during cooking. In industry, we also select and use different agitators according to the purpose. The following table shows a summary of the purpose and results of agitation, and examples of representative agitators.

| Agitation | Purpose | Result | Representative agitator |

| Homogenization | Emulsion | Homogenizer | |

| Suspension | (Ultrasonic/ High-speed blade/High pressure) | ||

| Dispersion | Dispersion | High-speed blade | |

| Slurry | Bead mill | ||

| Paste | Roll mill | ||

| Mixing | Mixture | Agitator blade | |

| Static mixer | |||

| Kneading | Paste | Kneader | |

| Cake | |||

| Mass transfer | Promotion of reaction and dissolution | Agitator blade | |

| Heat transfer | Agitator blade |

Explanation of terms related to agitation

– Agitation: stirring, agitating.

– Homogenize (homogenization): All parts of a substance are uniform and have the same properties and state.

– Dispersion (dispersion system): A mixed system in which one substance is dispersed as fine particles among other substances or among the same substance in a different state. Scattered particles are referred to as dispersoids, and solutes, as dispersion media. Suspension, emulsion, colloid solution, true solution, etc. In the ink industry, it is also called a “mill”.

– Mixture/admixture: Mixtures of substances with different properties. Blending.

– Kneading/admixture: Kneading highly viscous liquid or clay-like material with strong shearing force.

– Mass transfer: Phenomenon in which a substance moves in a solid or a liquid mainly due to the diffusion effect.

– Emulsion: A mixture in which fine particles of solids are dispersed in a liquid.

– Slurry: Thick gruel-like substance. Suspension of liquid and solid particles.

– Paste: A paste-like substance. Kneaded substance. (Viscosity of paste is higher than that of slurry. Note that this may depend on the industry.)

– Solids: Solid objects. Solid substances. Opposite of liquid.

Principle and characteristics of planetary centrifugal mixer

Why is agitation possible without agitator blades?

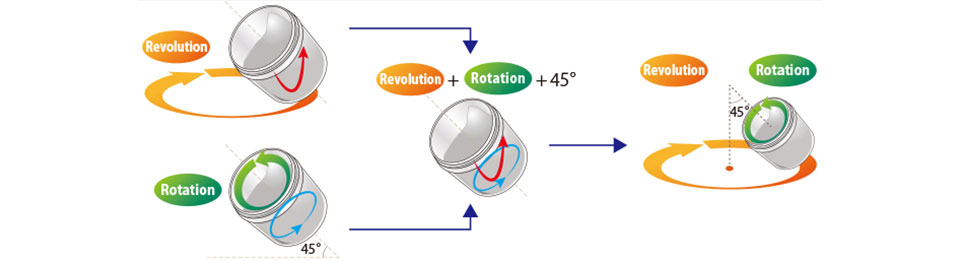

With a planetary centrifugal mixer, even highly viscous materials can be homogeneously agitated in a short time. There are three important factors to realize this. (1) The container revolves in the planetary centrifugal mixer. (2) The revolving container itself rotates. (3) Further, the rotation axis of the container is tilted to 45 degrees.

1. Revolution: Moves the material away from the center with “centrifugal force of revolution”.

2. Rotation: “Rotation of the container” causes flow of the material (rotation and shearing).

3. 45 degrees: Because of the 45-degree tilt of the rotation axis, the flow of material inside becomes a three-dimensional velocity field.

Furthermore, the flow velocity (direction) changes suddenly between the liquid surface and the container wall, causing complicated flow and strong shearing force. This shearing force makes droplets and particles smaller and increases their dispersibility. (Air bubbles are also dispersed finely.) As a result, uniform agitation can be achieved in a short time without using agitator blades.

What is the difference between atmospheric-pressure type and vacuum type?

Thinky’s planetary centrifugal mixer consists of two types: atmospheric-pressure type and vacuum type. In the agitation process, bubbles often cause problems, and in such a case, one of these two types can be used depending on the purpose and usage. The atmospheric-pressure type mixer can remove air bubbles of several hundred microns order, which are visible to the naked eye. The vacuum type mixer can be used when invisible micron-sized bubbles are to be removed. Conventionally, following agitation in a mixer, deaeration is accomplished with a desiccator, etc., which takes a long time. The planetary centrifugal mixer can achieve deaeration while agitating without worrying about overflowing, greatly reducing time.

Let’s see how each deaeration is actually done.

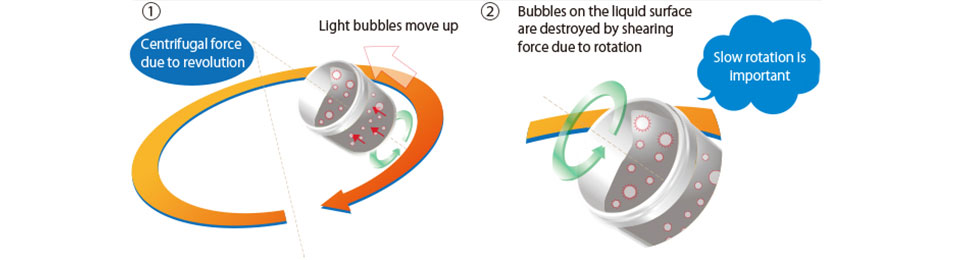

Deaeration by atmospheric-pressure type (suitable for materials with relatively low viscosity)

Most of the atmospheric-pressure type mixers are equipped with the “deaeration mode”. By changing the balance between revolution speed and rotation speed, deaeration takes place on the basis of the following principles:

1. “Centrifugal force due to revolution” forces light bubbles to the liquid surface.

2. By applying slow rotation that engulfs no bubbles (i.e., deaeration mode), bubbles that have risen to the liquid surface are destroyed by shearing force.

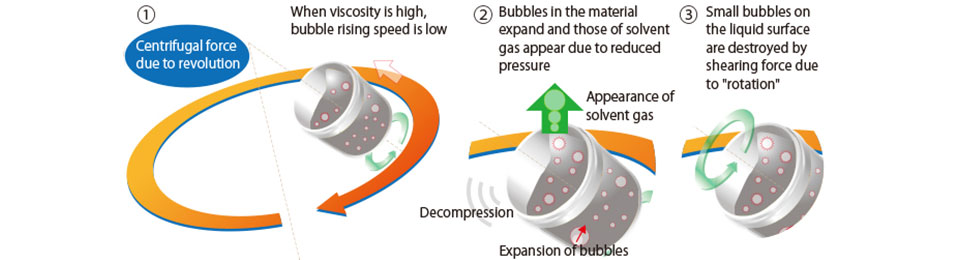

Vacuum type defoaming (suitable for materials with relatively high viscosity)

Defoaming takes place on the basis of the following principles:

1. When viscosity is high, bubble rising speed is low, and bubbles are carried to the surface by convection of the material.

2. Bubbles expand due to reduced pressure and are destroyed. Solvent gas bubbles also appear.

3. Small bubbles are also destroyed on the liquid surface by shearing force due to “rotation”.

* If you have trouble deciding which type suits your needs most, you can request for a demonstration for comparison. Please feel free to contact us.