Pulverization 2: Pulverization method and pulverizer

October 31, 2019|Glossary

Dry pulverization and wet pulverization(*1)

Dry pulverization and wet pulverization are the methods of pulverization. The differences between the two are summarized below.

| Dry pulverization | Wet pulverization |

|---|---|

| – Pulverize in air or inert gas – Pulverization into particles of various sizes ranging between large and fine is possible – It is unlikely that particle diameter is reduced to 3 μm or less –> the so-called “3 μm barrier” – Low cost compared to wet pulverization |

– Pulverized in liquid such as water – Pulverization target is fine particles and ultrafine particles – The ultimate particle size can reach nm order – Can have more contaminants than dry pulverization – High cost compared to dry pulverization |

Dry pulverization is used in a wide range of fields because of its features. The size of pulverized products is generally reduced to micron level. In some cases, pulverization to submicron level is possible, but there are problems, such as aggregation and difficulty of collection.

Wet pulverization is capable of grinding to submicron level (ultrafine pulverization), which is difficult with dry pulverization. In addition to the pulverization of primary particles, wet pulverization also includes disintegration (= mechanical pulverization) and dispersion. In recent years, miniaturization of materials is often required, and not only pulverization but also disintegration and dispersion operations have become more and more important.

(* Disintegration (= mechanical pulverization) is one of the processes of dispersion. An external mechanical force is applied to agglomerated particles to loosen them almost without the formation of new particle surfaces and to reduce the size of agglomerated particles.)

Types of pulverizers

The particle size that can be reduced by a single machine differs depending on the pulverizer. For this reason, several pulverizers are often used in series.

There are also a wide variety of pulverization methods, such as continuous pulverization versus batch pulverization (batch type) and dry pulverization (dry milling or grinding) versus wet pulverization (wet milling or grinding). It is important to select a pulverizer suitable for the purpose, taking into account the type and size of material to be pulverized (object to be pulverized), the target particle size, the conditions, etc.

Representative pulverizers(*1)(*2)

| Classification of pulverization operation | Size of pulverized material (ground particle size) | Main pulverization mechanism | Examples of pulverizer |

|---|---|---|---|

| Crushing |

Meter order ⇒10cm or less |

Compression |

Jaw crusher Gyratory crusher |

| Medium crushing |

10cm ⇒10mm or less |

Compression Impact and shear Compression and shear |

Crushing roll Hammer mill Roller mill |

|

Pulverization / (fine)grinding / milling |

1mm ⇒10μm or less |

Impact Impact and friction Shear and friction Friction, impact, and compression |

Jet mill Ball mill Vibratory ball mill Planet mill |

| Ultrafine grinding |

10μm ⇒1μm or less |

Impact, shear, and friction Friction, impact, and compression |

Wet medium agitation type grinder (bead mill, attritor, etc.) Planetary mill (depending on conditions) |

* There are various classifications of pulverization operation. Pulverization may be classified into rough, medium, small crushing, coarse, fine, and ultrafine grinding.

Thinky pulverizer

Thinky Corporation has developed a rotation and revolution nano-pulverizer “Nano Pulverizer NP-100” for the purpose of nano-size pulverization.

Principle of pulverization and features

The rotation and revolution nano-pulverizer is a batch-type wet pulverizer that can perform pulverization and disintegration into about 1 mm or less or even about 100 nm (several dozens of nm by disintegration). It is a type of planetary ball mill (planetary mill) or bead mill.

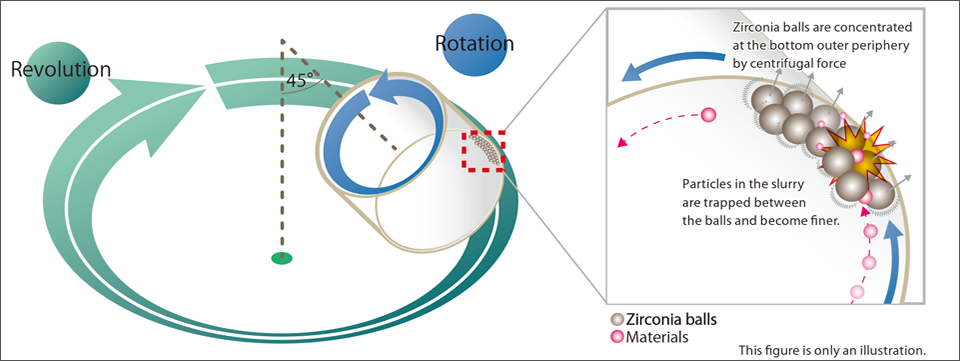

Introduce balls (also called beads), which are grinding media, into a grinding container together with slurry. The grinding container revolves clockwise at a high speed with a 45° tilt angle while rotating counterclockwise at the same time (see “Mixing”). Please refer to the figure below.

This high-speed revolution and rotation cause the grinding media in the container to concentrate on the bottom outer periphery of the container. There, the slurry undergoing convection motion in the container are affected by a combination of shear force, friction force, impact force, and become fine particles. Because the grinding container is inclined at 45°, the concentration of the grinding media on the bottom outer periphery of the container becomes higher. Therefore, only a small amount of grinding media is required. Furthermore, this inclination can suppress the rise of the slurry, enabling efficient pulverization without waste.

Zirconia balls receive kinetic energy through the revolution and the rotation with the inclination of 45°, and are concentrated at the bottom outer periphery without rising along the container inner wall. At the same time, particles in the convecting slurry in the container are trapped between the balls where they are affected by a combination of shear force, friction force, impact force, etc., and are finely pulverized.

Tasks that can be accomplished with the rotation and revolution nano-pulverizer

The results obtained depend on the shape and hardness of pulverized materials, and composition of slurry.

| Pulverized particle size | Size of pulverized particles | Examples | |

|---|---|---|---|

| Pulverization / grinding / milling | Minimum particle size<1 mm |

Average particle size (primary particle size) 100 ~ 200 nm |

Pharmaceuticals, drug candidate compounds, metal oxide, carbon, etc. |

|

Disintegration Dispersion |

Secondary aggregation<1 mm |

Average particle size Up to several tens of nm |

Organic pigment, metal oxide, carbon, etc. |

Materials for which the rotation and revolution nano-pulverizer has difficulty or no possibility of processing.

Based on the results of previous experiments, it has been found that Thinky’s rotation and revolution nano-pulverizer has difficulty processing the following materials:

– Elastic materials (resin, rubber, natural materials, etc.)

– Materials readily affected by heat (protein, cellulose, etc.)

– Materials that are soluble in solvent

– Fiber-like, flaky materials (CNF, exfoliation of graphite, etc.)

– Ductile materials (metal)

(*1) Hiroshi Sakamoto: “Crushing and grinding”, Resources and Materials Vol. 113, No. 12, 899-903 (1985).

(*2) Introduction to Powder Engineering, 52-57, Association of Powder Process Industry and Engineering, Japan.

(*3) Yoshiteru Kanda: “Study on research and technological history of grinding”, Journal of the Association of Materials Engineering for Resources Vol. 9, No. 2, 87-110 (1996).

(*4) Toshio Inoue: “What contributes to the improvement of grinding efficiency?” Journal of the Society of Powder Technology Vol. 22, No. 6, 71-76 (1985).

(*5) BSI Institute website “Fertilization Engineering” – Grinding.

(*6) Tsutomu Nakayama: Bead mill for making ultrafine particles and nanoparticles p23-28, p29, p34-35.

(*7) Powder Terms Pocket Book, Association of Powder Process Industry and Engineering, Japan.