Background of Development of Nano Pulverizer NP-100 that Realizes Nano Pulverization in a Short Time

February 18, 2020|Topic

In this issue, we would like to share with you the background of the development of Nano Pulverizer NP-100, which is used for the nano pulverization of lithium-ion battery materials and inorganic materials.

Preparing slurries for new drug development served as springboard

What prompted the development of Nano Pulverizer NP-100 was the request to prepare slurries for new drug development made by Mr. Hashimoto (currently Thinky’s technology advisor), who was working for a leading pharmaceutical company before joining Thinky.

His request was as follows: “I want to develop a good drug, thereby contributing to society. In order to do so, it is necessary to reduce poorly water-soluble agents into nanoparticles to increase solubility.” For this, I want you to build a Thinky Mixer that has a higher speed.” We began working on the development of a Thinky Mixer that can generate nanoparticles.

Basic issues were resolved through slurry preparation by Mr. Hashimoto, so we assumed at first that we would be able to realize nanosizing as an extension of the existing Thinky Mixer quite easily. However, it began to dawn on us that it would be difficult that way.

Milk mistakenly stirred in coffee as clue for temperature control

One of the challenges was how to control the temperature of a material. In order to reduce a material into nanoparticles, we had to rotate the Thinky Mixer faster than usual, but when the media for pulverization was rotated at a high speed in the container, its temperature shot up in an instant. Not only did this damage the Thinky Mixer, it changed the nature of the material and erased its efficacy as well. Conversely, if we reduced the rotation speed, temperature rise would be curbed but the material would not be pulverized sufficiently.

We held consultations with a cooler developer but was told that it had never cooled the material to be rotated, and we were unable to find a good way around that. We were thus compelled to start thinking about incorporating a freezing device into the Thinky Mixer using the cooler of a centrifuge in Mr. Hashimoto’s lab as reference. When we switched on our prototype freezing device, the temperature inside began falling right away, which gave us false hope, but it did not fall enough to cool the material.

The freezing device of a centrifuge is designed specifically for biological samples that do not generate heat in the first place, so it does not anticipate a case in which there is a source of heat like this one. Enhancing the freezing device’s performance yielded a slight change that fell way short of our expectations. Under ordinary circumstances, we would like to use water, which is efficient for heat exchange, but could not add it into the rotating part. Furthermore, the container for the material also served as an insulator, so generated heat was not transferred externally well, either. Thinking that this approach to cooling had limitations, we were on the brink of giving up.

But then, one day, I had an opportunity to stop by at a coffee shop with my colleagues. I normally have my coffee black but mistakenly added milk into my coffee. When I used a spoon to swirl milk in my coffee, the swirl disappeared and the milk diffused in an instant. This instantaneous movement of milk looked like chilled air in the machine and I had a flash of insight that this might work.

The chilled air in the machine should be rotating with the material being rotated to form a swirl. I thought that if I put an obstacle like a spoon in this swirl, the chilled air would diffuse into the material, thereby cooling it more rapidly. When I made a prototype of an obstacle in no time and checked the temperature, I found that the temperature was markedly lowered. After verifying the appropriate shape, size, and number of obstacles and designing one, I was able to realize sufficient cooling performance and thereafter obtained a patent for this way of cooling.

The atmosphere in the chamber is cooled down to -20 ℃.

We had a difficult time realizing the target particle diameter …

The other challenge was the realization of the target particle diameter. In the beginning, we thought that the target particle diameter would be realized if we increased the number of rotations. But after the particle diameter became less than 1 μm or so, pulverization ceased to continue. When we changed the number or size of media, solvents, and conditions little by little over time, we ended up reducing the particle diameter although it was far from the target particle diameter. In addition, the particle diameters were irregular.

Under such circumstances, we happened to obtain a good experimental result. However, because the result was not reproducible, at first, we thought that it must be an experimental error. We noticed that only when the bottom of the container was scraped with streaks was such a favorable result produced.

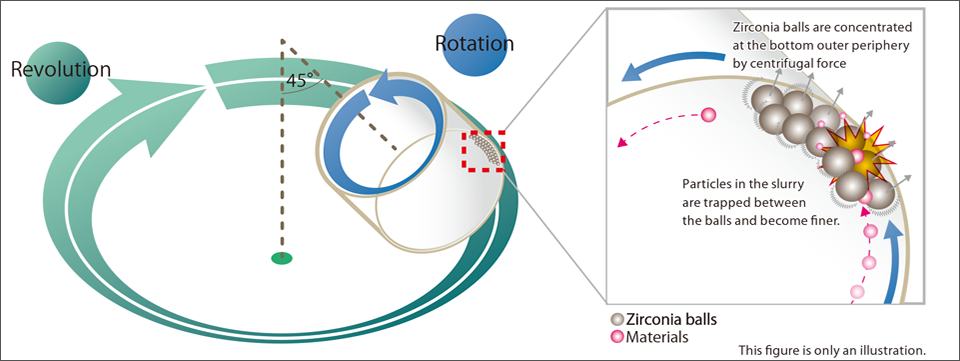

Based on a hypothesis that a pulverized medium or material passes through these streaks, which, in turn, promotes pulverization and produces a good outcome, we came up with the idea of changing the shape of the container (*), thereby increasing the degree of pulverization. After developing a prototype and conducting an experiment, a clear peak, which was proof of the formation of nanoparticles, was obtained. Under the right conditions, the material could be reduced to around 100 nm in size in a few minutes and be pulverized without losing its crystalline nature.

This was when the planetary centrifugal Nano Pulverizer NP-100 was born.

(*) For the actual shape, please visit our booth at an exhibition or see a demo.

Revolution/rotation + shape of container makes nano pulverization possible.(*The figure is for illustrative purposes only.)

It took a long time to bring Nano Pulverizer NP-100 to completion. Its success could be attributed to support not only from people inside the company but also from others in the industry, including Mr. Hashimoto.

This device is used for developing new materials, such as electronic or battery materials, as well as new drugs. We are extremely pleased that Nano Pulverizer NP-100 is of help to people this way.

For details of the principles of pulverization and the features of Nano Pulverizer NP-100, please visit the following:

See [What is pulverization? <2>~ Method of pulverization and pulverizers ~]